fluid coupling

characteristics

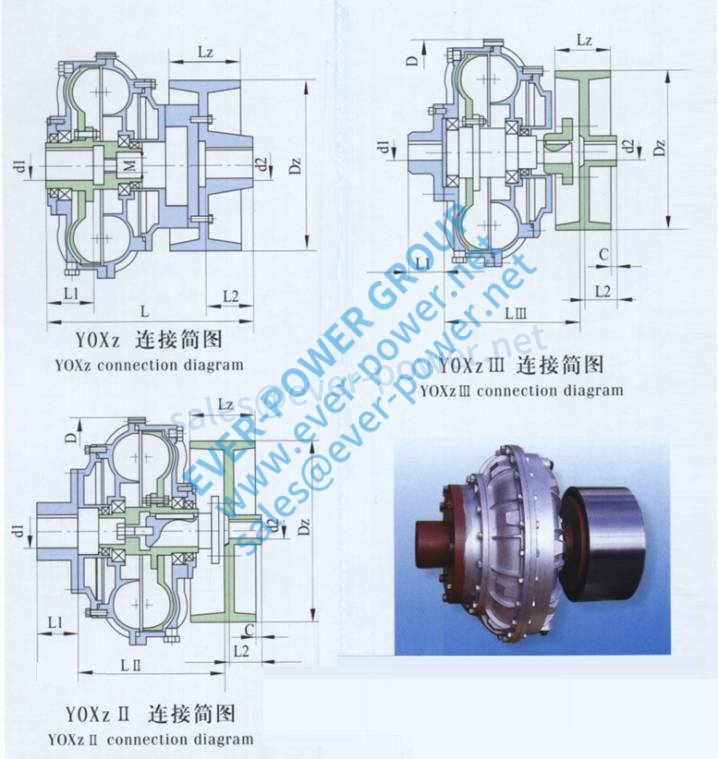

eleven dimensions

Designs obtainable using couplings (Para-Flex and DGF Gear) or V-Belt drives

Accommodates up to four.seventy five inch shafts and 1400 horsepower applications

Sleek, managed acceleration with customizable startup torques

Motor starts off under no load, allowing the use of common NEMA design and style B motors and

No bodily connection is current, allowing for defense underneath overload conditions

Widespread Industries

Air Managing

Mining

Paper & Forest

frequent applications

Conveyors (Bulk Substance Dealing with)

Any application requiring overload safety

Any application with a large-inertia startup

Overview

Fluid coupling on Transfluid’s

A fluid coupling is composed of a few components, in addition the hydraulic fluid:

The housing, also acknowledged as the shell[five] (which need to have an oil-restricted seal around the generate shafts), includes the fluid and turbines.

Two turbines (fanlike components):

1 connected to the enter shaft acknowledged as the pump or impeller,[5] principal wheel[five] enter turbine

The other connected to the output shaft, acknowledged as the turbine, output turbine, secondary wheel[5] or runner

The driving turbine, known as the ‘pump’, (or driving torus[a]) is rotated by the prime mover, which is usually an inner combustion motor or electric powered motor. The impeller’s movement imparts each outwards linear and rotational motion to the fluid.