Product Description

Product Name: OEM/ODM Engine Gear

Engine Gear Manufacturing Plant of Xihu (West Lake) Dis.Feng Motor Corporation(DFM23)

Global OEM supply to CHINAMFG and Volvo worldwide.

Engine Gear Plant of DFM (DFM23 for short) was founded in 1969, which is a large production base for auto parts. We have perfect parts and components technology development capabilities thanks to our advantage of strong tool and R&D capability.

Staff: There are 795 employees in DFM23 and 156 of them are technical engineers.

Equipment: The plant owns more than 852 machines, including 103 advanced machines which were imported.

Forging and machinining Equipment:

Quality Test Equipment:

Certifications:

ISO9001(2004);

ISO/TS16949(2004.11);

ISO14000(2005.3);

OHSASI18000(2005.3);

ASES(2571.10)

Product Development Capability:

Strong technical strength for CHINAMFG system optimization design, noise reduction, strength check and so on.

Quick Response; R&D with Customer.

Full Quality Control; Self Design/ Self made tooling

Informatization Technology Applied in Plant:

PMS & ERP & MES system come into service in March 2017.

Technical Patents/ Intellectual Property:

Now we own 12 patents.

New Technology Applications:

Anti-wear phosphating; Shot Peen; High speed Hobbing; High speed teeth grinding; Continuous heat treatment

Honing Hole; Hard turning; Inner hole and end-face grinding.

Gear Product Development Plan:

Global Supply to Cummins

We provide nearly 200 kinds of gears for CHINAMFG global 15 OEM plants & cooperative partners, 3 spare parts service center, products cover 2.8L-95L.

At present, we are sole supplier for 45L above heavy-duty engine gear; Provide optimized design proposal for CHINAMFG engine gear, participate in R&D and other technical support and comprehensive service ability.

We manufature according to customer’s drawings and requirements,

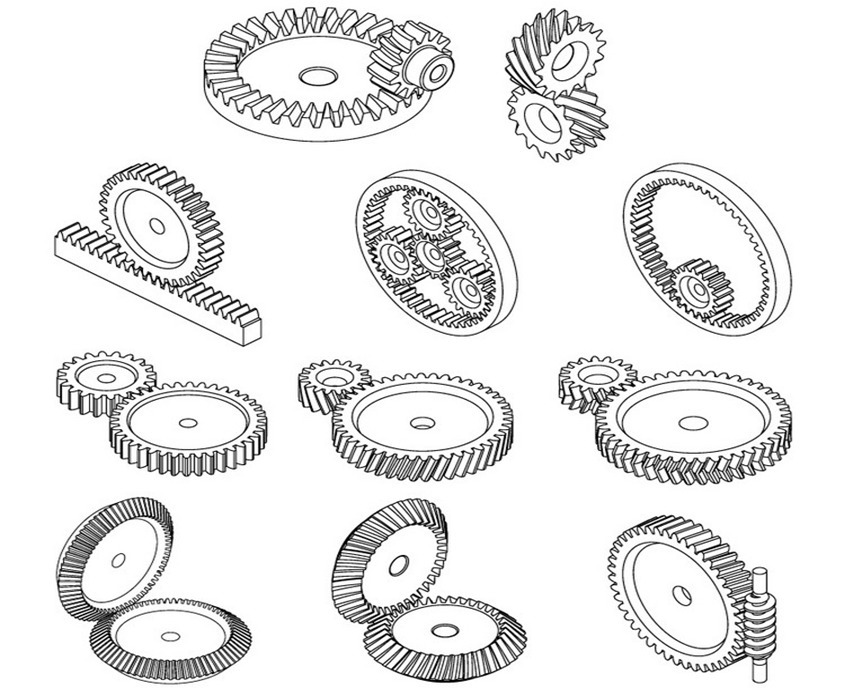

Type of Gears We can supply:

Gear Crankshaft / Gear Camshaft / Gear Fuel pump / Gear Air compressor / Gear from moving

Material:

20CrMnTiH, 20CrMo, 20MnCr5, SAE8620H, 17CrNiMo7-6

Weight(kg): 0.6-30

Size(mm): 50-360

Gear Precision: ISO6 Level

Here’s why our products stand out:

1. Extensive Product Range: We offer a diverse selection of buses, school buses, andspecial purpose vehicles to cater to various transportation needs. Whether yourequire standard buses for public transport, specialized school buses withenhanced safety features, or custom-built special purpose vehicles for specificapplications, we have a solution to meet your requirements.

2. Superior Quality and Reliability: Our vehicles are manufactured to the highestindustry standards, ensuring exceptional quality, reliability, and longevity. Wecollaborate with reputable manufacturers and conduct rigorous quality controlchecks to deliver products that exceed customer expectations. Our commitmentto CHINAMFG is reflected in every vehicle we offer.

3. Cutting-Edge Technology: We incorporate advanced technologies andinnovations into our vehicles to enhance performance, efficiency, and safety.From fuel-efficient engines and intelligent control systems to state-of-the-art

safety features and eco-friendly designs, our products are at the forefront ofautomotive technology.

4. Customization Options: We understand that every client has unique needs ancpreferences, Therefore, we provide customization options to tailor our vehiclesaccording to specific requirements. Whether it’s seating capacity, interiorconfigurations, accessibility features, or branding elements, we work closely withour clients to deliver personalized solutions.

5. Focus on Safety: Safety is our top priority. Our school buses are designed withcomprehensive safety features, including reinforced structures, advanced brakincsystems, and integrated safety technologies. We prioritize passenger and driversafety to provide peace of mind for both educational institutions and parents.

6. Exceptional After-Sales Service: Our commitment to customer satisfactionextends beyond the purchase. We provide reliable after-sales service andsupport, including spare parts availability, technical assistance, and maintenanceguidance. Our dedicated team ensures that our customers receive prompt andefficient service throughout the ownership lifecycle.

FAQ

FAQ

1. Q:Why choose you?

A:We are the specialized distributor authorized by the Xihu (West Lake) Dis.feng Motor Corporation (DFM), which headquartered in HangZhou, China. And the manufacturing plant of our special vehicle is military enterprise which attaches a greatest importance to the quality of the products and service.

2. Q:How to visit your factory ?

A:You will be welcomed here for factory inspection. It takes about 2 hours from ZheJiang or ZheJiang to HangZhou by air, or 3 hours by speed train from HangZhou to HangZhou.Online visit is also avaliable for you.

3. Q:How to pack the truck?

A:It will be waxed and shipped by bulk carrier, RORO ship or container.

4. Q:Could your company modify the standard product depends on my request?

Yes. Our company is specialized in researching and designing various of special purpose vehicle and spare parts. We can provide any product according to your demand.

5. Q:Can I customize the painting and logo?

A:Yes,of course, we can paint the truck as your requirement.

6. Q:What’s your quality guanrantee or after sales service?

A: Our guarantee is 1 year, the key parts damage not caused by improper operation, it will free maintenance and replacement. And we also provide online support, Video technical support and spare parts available.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Forging+Machining |

| Toothed Portion Shape: | Spur Gear |

| Material: | Forging Gear |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the process of shifting gears smoothly in a manual car?

Shifting gears smoothly in a manual car is a skill that requires coordination and practice. Here’s a detailed explanation of the process:

1. Clutch Operation:

Before shifting gears, it’s essential to understand the operation of the clutch pedal. The clutch is used to temporarily disconnect the engine’s power from the transmission, allowing smooth gear engagement. To shift gears smoothly:

- Press the clutch pedal fully to disengage the clutch.

- Keep the clutch pedal depressed throughout the shifting process.

2. Throttle Control:

While shifting gears, it’s important to synchronize the engine speed (RPM) with the speed of the transmission. Here’s how to manage the throttle:

- Gradually release the accelerator pedal as you prepare to shift.

- Avoid abruptly lifting off the throttle, as it can cause a sudden drop in engine RPM.

3. Shifting Process:

Once the clutch is fully depressed, and the throttle is appropriately controlled, follow these steps to shift gears smoothly:

- Move the gear lever to the desired gear position while keeping the clutch pedal depressed.

- Avoid applying excessive force or rushing the gear lever movement.

- Wait for a brief moment after moving the gear lever to allow the gears to synchronize.

4. Releasing the Clutch:

After the gear lever is in the new position, smoothly release the clutch pedal while simultaneously modulating the throttle. Here’s how to do it:

- Gradually release the clutch pedal while applying gentle pressure on the accelerator pedal.

- Coordinate the release of the clutch with the increase in engine RPM.

- Avoid releasing the clutch too quickly or abruptly, as it can cause jerky gear engagement or stalling.

5. Practice and Smooth Transitions:

Smooth gear shifting requires practice and familiarity with the specific vehicle’s clutch and gearbox characteristics. Consider the following tips for achieving smooth transitions:

- Practice shifting gears in an open area with minimal traffic until you become comfortable.

- Develop a feel for the clutch engagement point, which is the position where the clutch starts to transmit power.

- Anticipate the need for gear changes by observing the engine RPM and road conditions.

- During upshifting, aim to shift gears when the engine RPM reaches a moderate level, typically between 2,000 and 3,000 RPM.

- During downshifting, match the engine RPM to the lower gear’s appropriate range to ensure smooth engagement.

Remember, mastering smooth gear shifting requires practice, coordination, and a good understanding of your vehicle’s clutch and gearbox. With time and experience, you’ll be able to shift gears seamlessly and enjoy a smoother driving experience.

What is a continuously variable transmission (CVT) and how does it work in cars?

A continuously variable transmission (CVT) is a type of automatic transmission that provides an infinite number of gear ratios within a specific range. Here’s a detailed explanation of how it works:

In a traditional transmission, gears of different sizes are used to achieve different gear ratios. These gears have fixed ratios, and the transmission shifts between them to adjust the speed and torque output. In contrast, a CVT uses a different mechanism to vary the gear ratios.

1. Pulleys and Belt/Chain System:

A CVT consists of two pulleys connected by a metal belt or a chain. Each pulley has two halves that can move closer together or farther apart. One pulley is connected to the engine, and the other is connected to the wheels.

2. Variable Pulley Diameter:

The pulleys in a CVT have variable diameters. As the pulley halves move closer together, the effective diameter decreases, and as they move farther apart, the effective diameter increases. This adjustment of the pulley diameters allows for continuous variation of the gear ratio.

3. Belt/Chain Movement:

The metal belt or chain runs between the two pulleys. When the effective diameter of one pulley decreases, the belt or chain moves towards the larger diameter on the other pulley. As a result, the contact point on the pulleys changes, altering the effective gear ratio.

4. Hydraulic or Electronic Control:

To control the movement of the pulleys, a CVT uses a hydraulic or electronic control system. This system monitors various factors, such as vehicle speed, engine load, throttle input, and acceleration demands, to determine the optimal gear ratio. It then adjusts the position of the pulley halves accordingly.

5. Seamless Gear Ratio Changes:

Due to the continuous variation of the pulley diameters, a CVT provides seamless gear ratio changes. It can continuously adjust the gear ratio to keep the engine operating at its most efficient RPM for a given driving condition. This flexibility allows the engine to deliver power more effectively and improves fuel efficiency.

6. “Step” or “Shift” Modes:

Some CVTs offer “step” or “shift” modes to simulate traditional gear shifting. In these modes, the CVT may have predefined ratios or “virtual” gears that mimic the feel of gear changes. This can provide a more familiar driving experience for those accustomed to traditional automatic transmissions.

CVTs are known for their smoothness and fuel efficiency. By continuously adjusting the gear ratio to match the engine’s power output and the driving conditions, a CVT helps optimize fuel consumption. They are commonly found in smaller vehicles and hybrid cars.

However, it’s worth noting that CVTs may have a different driving feel compared to traditional transmissions, as the engine RPM can remain relatively constant during acceleration. Some drivers may prefer the stepped gear changes of conventional transmissions for a more engaging driving experience.

“`

What are the common types of automobile transmissions available?

There are several common types of automobile transmissions used in vehicles. Here’s a detailed explanation:

1. Manual Transmission: Manual transmissions, also known as “stick shift” or “standard” transmissions, require the driver to manually shift gears using a clutch pedal and gearshift lever. They typically have a set of forward gears, including first, second, third, fourth, and fifth (or sixth) gears, along with a reverse gear. Manual transmissions offer direct control over gear selection and are often preferred by enthusiasts for their engagement and control.

2. Automatic Transmission: Automatic transmissions use a torque converter and a complex system of planetary gears to automatically shift gears without driver intervention. They are the most common type of transmission in modern vehicles. Automatic transmissions provide smooth and convenient operation as they automatically select the appropriate gear ratio based on factors such as vehicle speed, engine load, and driver input. They typically offer “Drive” (D) mode for normal driving and may include additional modes like “Sport” (S) or “Economy” (E) for different driving preferences.

3. Continuously Variable Transmission (CVT): CVT is a type of automatic transmission that offers an infinite number of gear ratios within a specific range. Instead of using traditional gears, CVTs use a system of belts or chains and pulleys to provide seamless gear ratio changes. CVTs are known for their smoothness and fuel efficiency as they keep the engine operating at its most efficient RPM. They are commonly found in smaller vehicles and hybrid cars.

4. Dual-Clutch Transmission (DCT): DCT combines features of both manual and automatic transmissions. It uses two separate clutches for odd and even gears, allowing for quick and smooth gear shifts without interrupting power delivery. One clutch handles the current gear, while the other anticipates and prepares the next gear for engagement. DCTs provide fast and precise gear changes, making them popular in high-performance and sporty vehicles.

5. Automated Manual Transmission (AMT): AMT, also known as “Semi-Automatic Transmission” or “Clutchless Manual Transmission,” is essentially a manual transmission with automated clutch and gear shifting. Unlike traditional automatic transmissions, AMTs do not have a torque converter. Instead, they use actuators to control the clutch and gear selection based on the driver’s input or pre-programmed settings. AMTs are cost-effective alternatives to conventional automatic transmissions and are commonly found in entry-level or budget-friendly vehicles.

6. Sequential Manual Transmission (SMG) and Dual-Clutch Sequential Transmission: Sequential transmissions are commonly used in high-performance and racing vehicles. They allow for quick and precise sequential gear shifting without the need for a clutch pedal. SMGs use a single clutch, while dual-clutch sequential transmissions operate similarly to DCTs, with two clutches for improved performance and faster gear changes. Sequential transmissions provide rapid gear shifts, enhanced control, and are often controlled via paddle shifters mounted on the steering wheel.

These are some of the most common types of automobile transmissions available. Each type has its own advantages and characteristics, catering to different driving preferences, performance requirements, and fuel efficiency goals.

editor by Dream 2024-04-30