Product Description

| Product type | Transfer case motor gear |

| Material | Stainless steel,Steel(Iron,)Brass,Copper |

| Tolerance | ±0.01mm |

| Application | Tool industry |

| Shape | Custom |

| QC system | 100% inspection before shipment |

| Payment terms | T/T at sight, Paypal, Western Union,etc. |

| Lead time | 7-15 working days |

Fast product delivery

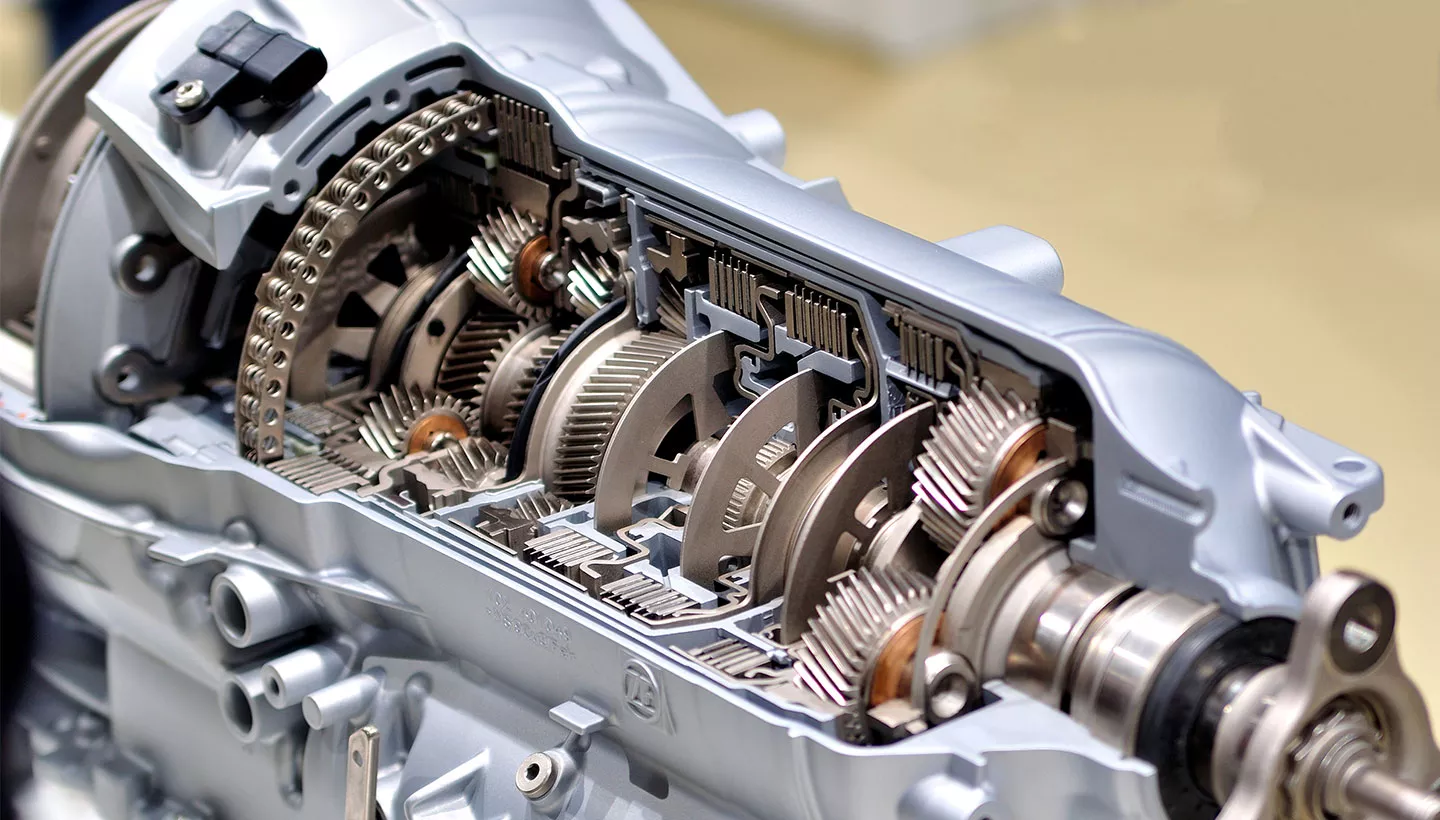

This gear is a 4WD transfer case motor gear, which is the gear on the motor of the car transfer case, if you need this, you can contact us to buy it, or you can buy it directly.

We have nearly 400 models of automotive transfer case gears. I believe there is always 1 that you need.

Product Description

Number of teeth: 69T

Tip circle diameter: 57mm

Gear thickness: 7.3mm

Model for transfer case: 600-908

This is a gear made of powder pressed and sintered. It is made of metal. Its raw materials can be copper based, iron based, stainless steel. Of course, other trace elements need to be added to increase the performance of the product.

If you need low cost and heavy use of metal parts. Please send us a message.

Product customization process

1. You send us drawing or sample.

2. We carry through project assessment.

3. We give you our design for your confirmation.

4. We make the sample and send it to you after you confirmed our design.

5. You confirm the sample then place an order and pay us deposit.

6. We start producing.

7. When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers.

8. Trade is done, thank you!!

Additional Capabilities CAD Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering

Product Price:Dear purchasers, if you need powder metallurgy part or look for products similar to our product images. You must be concerned about the price of the product as the powder metallurgy is customized parts basically, so we need to know the specific requirements of your products, such as providing product design drawings or samples. If you have neither of them, it doesn’t matter, contact us and we have sales staff to follow up timely. We will surely ask you more questions about the product, such as understanding the usage of product, so we can design products and materials according to the environment and characteristics. In that way, we can calculate an accurate to US$0.01 sales price for you. If we don’t have enough informations that the quoted price must be inaccurate, and it may be will increase your purchasing cost. Because we are the professional powder metallurgy manufacturer.

Why Choose Us

1. We have professional powder metallurgy production equipment and team;

2. We can accompany customers to develop products;

3. Just send an idea that you want to try, you don’t even need to know what powder metallurgy;

4. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

5. Our team will evaluate your inquiry and provide our offer within next 1~3 working days.

Some Parts We Manufacture

If the type you need is not listed above, please contact us to customize your special part.

About Us

DERYOUNG Technology company is a professional metal parts manufacturer, which with more than 20 years of experience in the development and production of sintered metals. Each year we produce more than 100 million premium sintered metal parts for our customers. We are mainly produce oil bearing, gear, and metal parts. We support our customers in the design and material selection of sintered parts, providing the best solution for your applied parts through our specialized equipment compression molds, furnaces, handling, sizing, deburring and impregnation processes.

Powder metallurgy process

FAQ

| Q: How can I get the quotation? |

| A: Please send us information for quote: drawing, material, weight, quantity and request,w can accept PDF, ISGS, DWG, STEP file format. If you don’t have drawing, please send the sample to us,we can quote based on your sample too. |

| Q: What’s your MOQ? |

| A: In general 1000pcs,but can accept low quantity in some special conditions. |

| Q: Do you provide samples ? is it free or extra ? |

| A: Yes, we could offer the sample for free charge but do not pay the cost of freight. |

| Q: What about the leading time for mass production? |

| A: Honestly, it depends on the order quantity. Normally, 15 days to 20 days after your deposit if no tooling needed. |

| Q: What if the parts are not good? |

| A: We can guarantee good quality,but if happened,please contact us immediately, take some pictures, we will check on the problem,and solve it asap. |

| Q: What is your terms of payment ? |

| A: Payment=1000USD, 30% T/T in advance ,balance before shippment |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Color: | Silver |

| Certification: | ISO |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a synchronized transmission system operate in manual cars?

A synchronized transmission system is a key component of manual transmissions in cars. Here’s a detailed explanation:

1. Purpose of Synchronized Transmission:

The purpose of a synchronized transmission system is to facilitate smooth and effortless shifting between gears in a manual transmission. It ensures that the rotational speeds of the input shaft (connected to the engine) and the output shaft (connected to the wheels) match before engaging the selected gear.

2. Synchronizer Rings:

The synchronized transmission system utilizes synchronizer rings, also known as synchro rings or blockers, to achieve synchronization. These rings are mounted on the transmission’s main shaft and are responsible for equalizing rotational speeds between the input and output shafts.

3. Cone Clutch Design:

The synchronizer rings feature a cone clutch design. When the driver selects a gear using the gear lever, the synchro ring corresponding to that gear slides over the gear’s dog teeth on the output shaft. The synchro ring and the dog teeth have matching cone-shaped surfaces.

4. Friction and Synchronization:

As the synchro ring engages with the dog teeth, it creates friction between the cone surfaces. This friction helps equalize the speeds of the input and output shafts. The synchro ring synchronizes the rotational speeds of the selected gear and the output shaft, allowing for smooth gear engagement.

5. Blocking and Engagement:

Once the rotational speeds are synchronized, the driver can easily engage the selected gear by pressing the clutch pedal and shifting the gear lever. The synchro rings facilitate the engagement by temporarily blocking the dog teeth on the output shaft, allowing the gears to mesh smoothly without grinding or clashing.

6. Double-Clutching:

In some older manual transmissions or vehicles with non-synchronized transmissions, a technique called double-clutching is required for smooth gear engagement. Double-clutching involves an additional step of disengaging the clutch after shifting out of the current gear, briefly engaging the clutch to match the engine speed with the transmission speed, and then shifting into the desired gear while the clutch is disengaged again. This technique is not necessary in modern synchronized transmissions.

7. Benefits of Synchronized Transmission:

The synchronized transmission system offers several benefits, including:

- Smooth shifting: The synchronizer rings enable seamless and smooth gear shifts, enhancing the overall driving experience.

- Reduced wear and tear: By equalizing rotational speeds before gear engagement, the synchronized transmission system minimizes wear and tear on the gears, synchro rings, and other transmission components.

- User-friendly operation: Synchronized transmissions are user-friendly, allowing drivers to shift gears effortlessly without the need for complex techniques like double-clutching.

In summary, a synchronized transmission system in manual cars utilizes synchronizer rings with cone clutch design to synchronize the rotational speeds of the input and output shafts. This enables smooth gear engagement and seamless shifting between gears, providing a user-friendly and efficient driving experience.

What is the impact of gear selection on fuel efficiency in a car?

Gear selection in a car has a significant impact on fuel efficiency. Here’s a detailed explanation:

1. Optimal Engine Speed:

Choosing the right gear allows the engine to operate at its optimal speed or within its “power band.” Each engine has a range of RPM (revolutions per minute) where it delivers the best balance of power and fuel efficiency. By selecting the appropriate gear, the engine can stay within this range, maximizing fuel efficiency.

2. Engine Load:

Gear selection affects the load on the engine. Higher gears, such as fifth or sixth gear, provide a higher gear ratio, reducing the engine’s rotational speed for a given vehicle speed. This reduces the load on the engine and can improve fuel efficiency, especially during highway driving where maintaining a steady speed is common.

3. Avoiding Over-Revving:

Shifting to a higher gear at the right time helps prevent the engine from over-revving. Over-revving occurs when the engine operates at excessively high RPM, which can waste fuel and potentially cause engine damage. By upshifting in a timely manner, the engine can run at a more efficient RPM range, leading to better fuel economy.

4. Acceleration and Deceleration:

The choice of gear during acceleration and deceleration also affects fuel efficiency. During acceleration, shifting up to higher gears smoothly and at appropriate RPM levels promotes fuel efficiency. Similarly, when decelerating, downshifting to lower gears while utilizing engine braking can save fuel by reducing the need for excessive braking and maintaining better control over vehicle speed.

5. Driving Conditions:

The impact of gear selection on fuel efficiency can vary based on driving conditions. For example, in hilly or mountainous terrains, downshifting to lower gears on uphill climbs can provide the necessary power while avoiding excessive fuel consumption. In stop-and-go city traffic, selecting lower gears can aid in smoother acceleration from a standstill, reducing fuel waste.

6. Manual vs. Automatic Transmissions:

The impact of gear selection on fuel efficiency can differ between manual and automatic transmissions. Manual transmissions offer more control over gear selection, allowing drivers to optimize fuel efficiency by choosing the most suitable gear for a given situation. On the other hand, modern automatic transmissions are designed to optimize fuel efficiency by automatically selecting the appropriate gear based on driving conditions and engine load.

In summary, gear selection plays a crucial role in determining fuel efficiency in a car. Optimal gear selection helps keep the engine operating at its most efficient RPM range, reduces engine load, prevents over-revving, and promotes smoother acceleration and deceleration. By understanding the relationship between gear selection and fuel efficiency, drivers can adopt driving habits that maximize fuel economy and reduce fuel consumption.

What is an automobile gear and how does it function in a vehicle?

An automobile gear is a mechanical component used in vehicles to transmit power from the engine to the wheels, allowing the vehicle to move forward or backward at different speeds. Here’s a detailed explanation of its function:

In a vehicle, the engine produces rotational power or torque. This power needs to be transmitted to the wheels in a controlled manner to enable the vehicle to move. The automobile gear system performs this task.

The primary function of the automobile gear is to change the gear ratio between the engine and the wheels, thereby adjusting the speed and torque output. It allows the engine to operate efficiently across a wide range of vehicle speeds and load conditions.

The most common type of automobile gear system is the manual transmission, consisting of multiple gears arranged in a specific sequence. The driver selects the appropriate gear based on the desired speed and road conditions.

When the driver shifts gears, the gearshift mechanism engages a specific gear combination. Each gear has a different gear ratio, which determines the speed and torque output. The lower gears provide higher torque output but lower vehicle speed, while the higher gears allow for higher speed but lower torque.

When starting the vehicle from a standstill, the driver typically engages the first gear, which provides the highest torque output. As the vehicle gains speed, the driver shifts to higher gears to increase the speed while maintaining optimal engine performance.

Inside the transmission, the gears are mounted on shafts and connected to the engine and the wheels through a series of gears, shafts, and clutches. When a gear is engaged, power is transmitted from the engine through the input shaft, and the corresponding output shaft connected to the wheels rotates at a speed determined by the gear ratio.

The gear ratio is the ratio of the number of teeth on the driving gear (connected to the engine) to the number of teeth on the driven gear (connected to the wheels). By changing the gear ratio, the speed of the wheels relative to the engine speed can be adjusted.

In addition to manual transmissions, there are also automatic transmissions and continuously variable transmissions (CVTs) used in vehicles. These transmission types use different mechanisms, such as planetary gearsets or pulley systems, to achieve gear ratio changes automatically without direct driver intervention.

Overall, the automobile gear system plays a crucial role in transferring power from the engine to the wheels, allowing the vehicle to move at different speeds. It enables the driver to control the vehicle’s acceleration, speed, and overall performance by selecting the appropriate gear ratio based on the driving conditions.

editor by Dream 2024-05-16