Product Description

Product Parameters

| product name | High Quality Stainless Helical Gear for New Energy Automobile Industry Machinery with ISO9001 |

| stainless steel , iron , aluminum ,bronze ,carbon steel ,brass , nylon etc . | |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping ,gear accuracy testing |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

Company Profile

Application Field

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts .

2. what services can we provide?

Accepted Delivery Terms: Fedex,DHL,UPS;

Accepted Payment Currency:USD,EUR,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union;

Language Spoken:English,Chinese

3. how can we guarantee quality?

1 .Always a pre-production sample before mass production;

2 .Always final Inspection before shipment;

3 .We have high-precision CNC gear grinding machine, high-speed CNC gear hobbing machine, CNC gear shaping machine, CNC lathe, CNC machining center, various grinding machines, universal gear measuring instrument, heat treatment and other advanced processing equipment.

4 . We have a group of experienced technical workers, more than 90% of the workers have more than 10 years of work experience in this factory, can accurately control the manufacturing of products and customer needs. We regularly train our employees to ensure that we can produce high-precision and high-quality products that are more in line with our customers’ needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

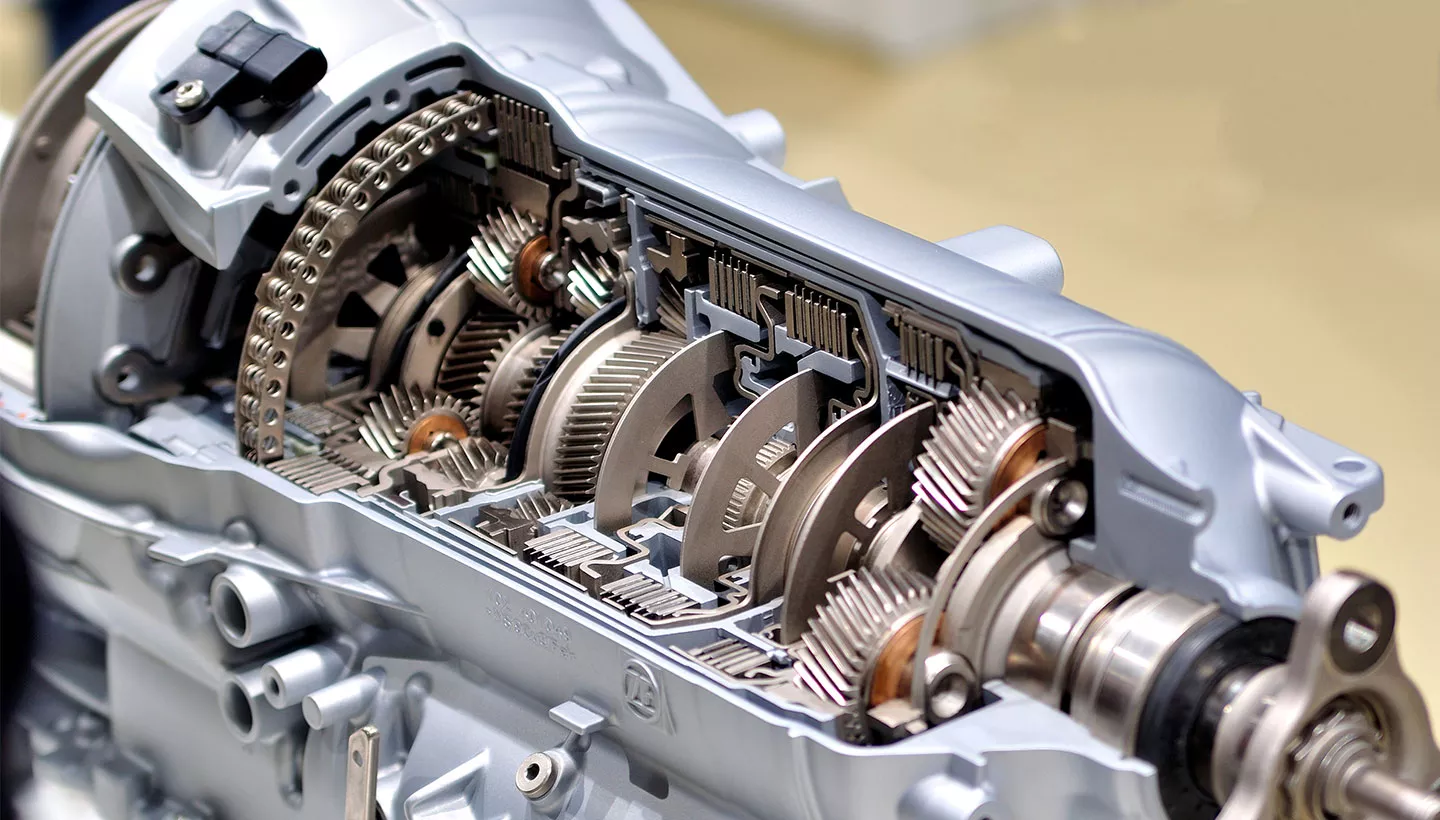

How does a synchronized transmission system operate in manual cars?

A synchronized transmission system is a key component of manual transmissions in cars. Here’s a detailed explanation:

1. Purpose of Synchronized Transmission:

The purpose of a synchronized transmission system is to facilitate smooth and effortless shifting between gears in a manual transmission. It ensures that the rotational speeds of the input shaft (connected to the engine) and the output shaft (connected to the wheels) match before engaging the selected gear.

2. Synchronizer Rings:

The synchronized transmission system utilizes synchronizer rings, also known as synchro rings or blockers, to achieve synchronization. These rings are mounted on the transmission’s main shaft and are responsible for equalizing rotational speeds between the input and output shafts.

3. Cone Clutch Design:

The synchronizer rings feature a cone clutch design. When the driver selects a gear using the gear lever, the synchro ring corresponding to that gear slides over the gear’s dog teeth on the output shaft. The synchro ring and the dog teeth have matching cone-shaped surfaces.

4. Friction and Synchronization:

As the synchro ring engages with the dog teeth, it creates friction between the cone surfaces. This friction helps equalize the speeds of the input and output shafts. The synchro ring synchronizes the rotational speeds of the selected gear and the output shaft, allowing for smooth gear engagement.

5. Blocking and Engagement:

Once the rotational speeds are synchronized, the driver can easily engage the selected gear by pressing the clutch pedal and shifting the gear lever. The synchro rings facilitate the engagement by temporarily blocking the dog teeth on the output shaft, allowing the gears to mesh smoothly without grinding or clashing.

6. Double-Clutching:

In some older manual transmissions or vehicles with non-synchronized transmissions, a technique called double-clutching is required for smooth gear engagement. Double-clutching involves an additional step of disengaging the clutch after shifting out of the current gear, briefly engaging the clutch to match the engine speed with the transmission speed, and then shifting into the desired gear while the clutch is disengaged again. This technique is not necessary in modern synchronized transmissions.

7. Benefits of Synchronized Transmission:

The synchronized transmission system offers several benefits, including:

- Smooth shifting: The synchronizer rings enable seamless and smooth gear shifts, enhancing the overall driving experience.

- Reduced wear and tear: By equalizing rotational speeds before gear engagement, the synchronized transmission system minimizes wear and tear on the gears, synchro rings, and other transmission components.

- User-friendly operation: Synchronized transmissions are user-friendly, allowing drivers to shift gears effortlessly without the need for complex techniques like double-clutching.

In summary, a synchronized transmission system in manual cars utilizes synchronizer rings with cone clutch design to synchronize the rotational speeds of the input and output shafts. This enables smooth gear engagement and seamless shifting between gears, providing a user-friendly and efficient driving experience.

What is the impact of gear selection on fuel efficiency in a car?

Gear selection in a car has a significant impact on fuel efficiency. Here’s a detailed explanation:

1. Optimal Engine Speed:

Choosing the right gear allows the engine to operate at its optimal speed or within its “power band.” Each engine has a range of RPM (revolutions per minute) where it delivers the best balance of power and fuel efficiency. By selecting the appropriate gear, the engine can stay within this range, maximizing fuel efficiency.

2. Engine Load:

Gear selection affects the load on the engine. Higher gears, such as fifth or sixth gear, provide a higher gear ratio, reducing the engine’s rotational speed for a given vehicle speed. This reduces the load on the engine and can improve fuel efficiency, especially during highway driving where maintaining a steady speed is common.

3. Avoiding Over-Revving:

Shifting to a higher gear at the right time helps prevent the engine from over-revving. Over-revving occurs when the engine operates at excessively high RPM, which can waste fuel and potentially cause engine damage. By upshifting in a timely manner, the engine can run at a more efficient RPM range, leading to better fuel economy.

4. Acceleration and Deceleration:

The choice of gear during acceleration and deceleration also affects fuel efficiency. During acceleration, shifting up to higher gears smoothly and at appropriate RPM levels promotes fuel efficiency. Similarly, when decelerating, downshifting to lower gears while utilizing engine braking can save fuel by reducing the need for excessive braking and maintaining better control over vehicle speed.

5. Driving Conditions:

The impact of gear selection on fuel efficiency can vary based on driving conditions. For example, in hilly or mountainous terrains, downshifting to lower gears on uphill climbs can provide the necessary power while avoiding excessive fuel consumption. In stop-and-go city traffic, selecting lower gears can aid in smoother acceleration from a standstill, reducing fuel waste.

6. Manual vs. Automatic Transmissions:

The impact of gear selection on fuel efficiency can differ between manual and automatic transmissions. Manual transmissions offer more control over gear selection, allowing drivers to optimize fuel efficiency by choosing the most suitable gear for a given situation. On the other hand, modern automatic transmissions are designed to optimize fuel efficiency by automatically selecting the appropriate gear based on driving conditions and engine load.

In summary, gear selection plays a crucial role in determining fuel efficiency in a car. Optimal gear selection helps keep the engine operating at its most efficient RPM range, reduces engine load, prevents over-revving, and promotes smoother acceleration and deceleration. By understanding the relationship between gear selection and fuel efficiency, drivers can adopt driving habits that maximize fuel economy and reduce fuel consumption.

What is an automobile gear and how does it function in a vehicle?

An automobile gear is a mechanical component used in vehicles to transmit power from the engine to the wheels, allowing the vehicle to move forward or backward at different speeds. Here’s a detailed explanation of its function:

In a vehicle, the engine produces rotational power or torque. This power needs to be transmitted to the wheels in a controlled manner to enable the vehicle to move. The automobile gear system performs this task.

The primary function of the automobile gear is to change the gear ratio between the engine and the wheels, thereby adjusting the speed and torque output. It allows the engine to operate efficiently across a wide range of vehicle speeds and load conditions.

The most common type of automobile gear system is the manual transmission, consisting of multiple gears arranged in a specific sequence. The driver selects the appropriate gear based on the desired speed and road conditions.

When the driver shifts gears, the gearshift mechanism engages a specific gear combination. Each gear has a different gear ratio, which determines the speed and torque output. The lower gears provide higher torque output but lower vehicle speed, while the higher gears allow for higher speed but lower torque.

When starting the vehicle from a standstill, the driver typically engages the first gear, which provides the highest torque output. As the vehicle gains speed, the driver shifts to higher gears to increase the speed while maintaining optimal engine performance.

Inside the transmission, the gears are mounted on shafts and connected to the engine and the wheels through a series of gears, shafts, and clutches. When a gear is engaged, power is transmitted from the engine through the input shaft, and the corresponding output shaft connected to the wheels rotates at a speed determined by the gear ratio.

The gear ratio is the ratio of the number of teeth on the driving gear (connected to the engine) to the number of teeth on the driven gear (connected to the wheels). By changing the gear ratio, the speed of the wheels relative to the engine speed can be adjusted.

In addition to manual transmissions, there are also automatic transmissions and continuously variable transmissions (CVTs) used in vehicles. These transmission types use different mechanisms, such as planetary gearsets or pulley systems, to achieve gear ratio changes automatically without direct driver intervention.

Overall, the automobile gear system plays a crucial role in transferring power from the engine to the wheels, allowing the vehicle to move at different speeds. It enables the driver to control the vehicle’s acceleration, speed, and overall performance by selecting the appropriate gear ratio based on the driving conditions.

editor by Dream 2024-04-24